If you are interested in the product and want more information, please leave your information .

Whatsapp : +86 15075770990

Wechat (China) : +86 15075770990

Email : sam@greatforming.com

Below is a brochure of our factory products, which can be viewed and downloaded.

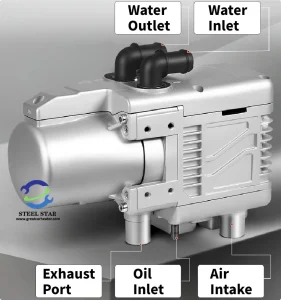

The core principle of a water-heated parking heater is “independent combustion heat generation + coolant circulation heat transfer.” That is, when the vehicle is off (parked), an independent fuel combustion system generates heat, heating the engine coolant. This heat is then transferred to the vehicle interior through coolant circulation, providing heating or preheating. This principle can be broken down into five key steps: “signal triggering → fuel combustion → heat exchange → heat circulation → intelligent temperature control,” as detailed below:

1. Core Principle: Combining Independent Combustion with Coolant Circulation

Water-heated parking heaters do not rely on engine power, but instead feature an independent “combustion-heat exchange-circulation” system. Essentially, they are a “small fuel-heating boiler” working in tandem with the vehicle’s cooling system. The specific process is as follows:

Signal Triggering: Start Command Transmission

The user sends a start signal via the remote control, an in-vehicle switch, or a timer. Upon receiving this signal, the device’s electronic control unit (ECU, whose core is a single-chip microcomputer) first checks basic conditions such as the vehicle’s battery voltage and coolant status. After confirming that there are no faults, it activates all components. Fuel Combustion: Independent Heat Generation

This is the source of heat, centered around “precise fuel injection + high-temperature ignition + complete combustion”:

The fuel pump draws fuel (diesel or gasoline, depending on the engine model) from the vehicle’s tank and pulses it, spraying fine droplets evenly onto the metal felt within the combustion chamber (avoiding direct fuel erosion and ensuring atomization).

Simultaneously, the glow plugs (or ignition pins) within the combustion chamber are rapidly heated to approximately 1000°C, vaporizing and igniting the atomized fuel, forming a stable flame.

The high-temperature exhaust gases generated by combustion are discharged outside the vehicle through a separate exhaust duct (completely isolated from the interior to prevent exhaust gas intrusion).

Heat Exchange: Coolant Heating

The combustion chamber is surrounded by a “coolant channel” (made of the same material as the engine cooling system pipes). The heat generated by the flame is rapidly transferred to the coolant within the channel, gradually raising the coolant temperature (typically a target temperature of 60-80°C, suitable for interior heating). Circulation Heat Transfer: Heat is transferred to the vehicle interior.

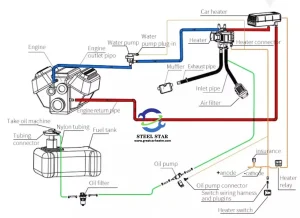

When the coolant temperature reaches a set value (generally 30-40°C), the electronic control unit activates the circulating water pump, pushing the heated coolant through a circuit consisting of the heater, engine radiator, and interior heater core.

When the hot coolant flows through the interior heater core, the heater (reusing the original vehicle’s air conditioner blower) starts, blowing the core’s heat into the vehicle interior, providing warmth.

At the same time, the circulating coolant preheats the engine, reducing wear during cold starts.

Intelligent Temperature Control: Stable Operation and Protection

The electronic control unit monitors the status of the engine in real time using a water temperature sensor, flame sensor, and overheating sensor.

If the coolant temperature is too high (e.g., exceeding 85°C), the fuel pump frequency will be reduced or combustion will be suspended to prevent overheating.

If no flame (e.g., low fuel) or a circuit fault is detected, the engine will immediately shut down and a fault code will be displayed for safety.

Small Water Heating Parking Heater Size

Technical Parameters

- Rated Voltage : 12V/24V (Can be customized according to your needs)

- Power : 5KW (Can be customized according to your needs)

- Fuel Consumption : About 0.38L/Hour

- Ambient Temperature : -40°~80°

- Product Weight : About 2.12KG

- Fuel Usage : Gasoline/Diesel/Methanol

Accessories List

Schematic

Brushed Motor

A brushed motor is a DC motor that uses brushes and a commutator to achieve mechanical commutation. It consists of a stator, rotor, brushes, and a commutator. Its working principle is based on the interaction of electromagnetic fields. The brushes and commutator work together to change the direction of the current, causing the rotor winding to rotate continuously in the stator magnetic field. It has the characteristics of fast starting, wide speed regulation range, and simple control circuit.

Brushed DC motors are low-cost and easy to maintain. They offer fast starting response, high starting torque, smooth speed changes, and virtually no vibration from zero to maximum speed. They can drive larger loads during starting. Brushless motors have high starting resistance (inductive reactance), resulting in a low power factor and relatively low starting torque. They produce a humming sound and strong vibration during starting, and can drive smaller loads during starting.

Website:

www.greatcarheater.com (English)

www.russianheater.com (Russian)

www.spanishheater.com (Spanish)